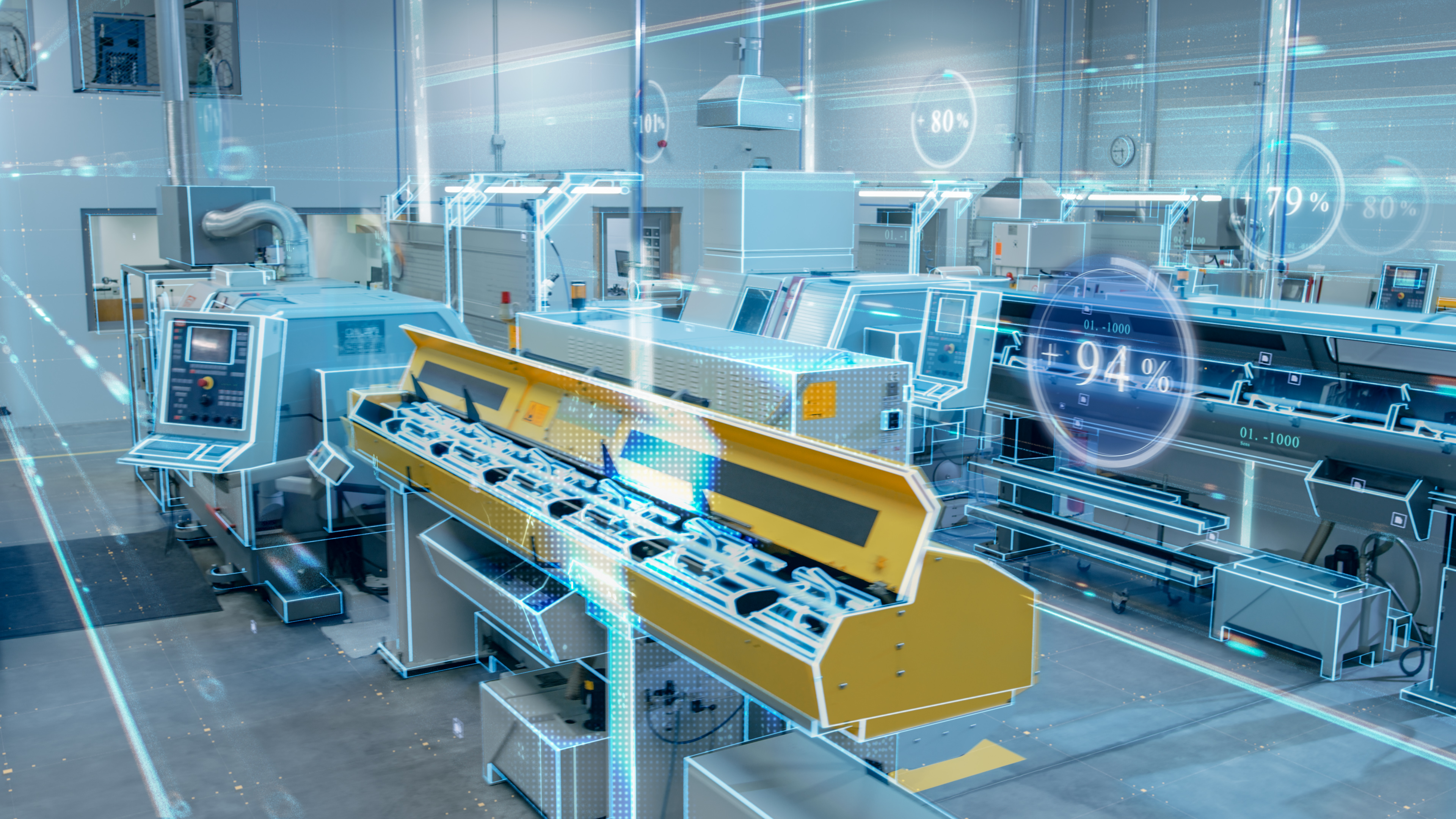

The manufacturing floor is buzzing with activity. CNC machines are cutting precision parts. Robots...

The manufacturing floor is buzzing with activity. CNC machines are cutting precision parts. Robots...

When production availability starts slipping, the instinct is often to add more maintenance tasks...

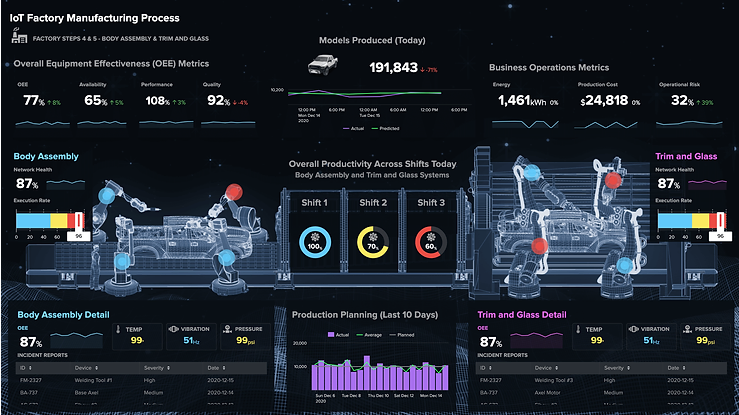

Organizations invest heavily in enterprise software to improve performance, streamline operations,...

Let’s be honest. This is how it usually goes: The pilot worked. The alerts came in. The data was...

This is Part 4 of our five-part series on overcoming the real barriers to advanced analytics and...

Predictive maintenance doesn’t require a rip-and-replace strategy. Here’s how manufacturers can...

This is Part 2 of our five-part series on overcoming the real barriers to predictive maintenance. ...

Struggling to turn pilot projects into full-scale PdM success? You’re not alone. We recently...

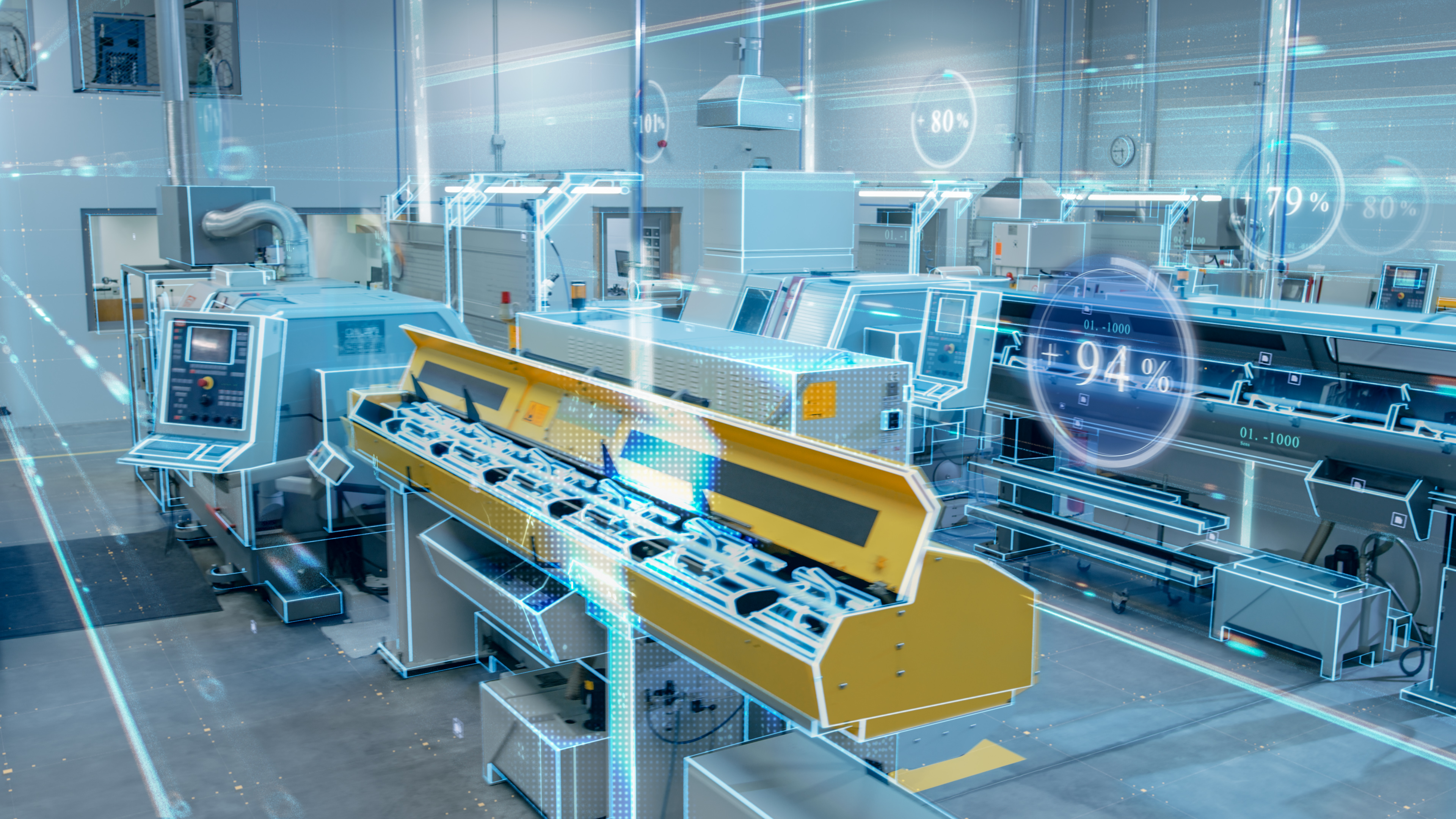

In the dynamic landscape of industrial operations, the significance of real-time monitoring for...

When considering whether to opt for a managed service or ownership model for various aspects of...

In the fast-paced world of manufacturing, efficiency is key to success. One of the most powerful...

In today's interconnected world, data has become the lifeblood of manufacturing and maintenance...

In today's competitive landscape, organizations are challenged to balance the cost, efficiency,...

In healthcare and life sciences, ensuring that equipment is calibrated, validated, and fully...